Our Story

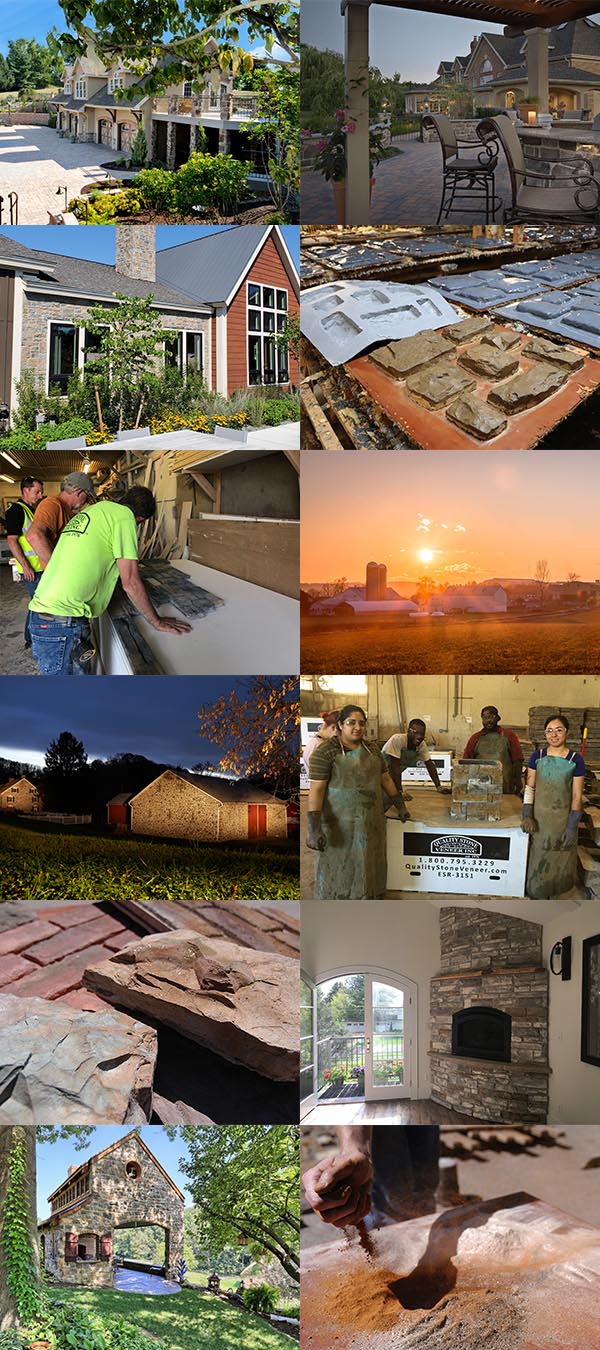

Quality Stone Veneer has been a family owned and operated business since the very first stone was cast in the late 70s.

The year is 1976 in the heart of the green rolling hills of Pennsylvania’s southeastern countryside. An inspired young laborer installing lap siding on residential homes notices a developing trend in the use of a then new building material, manufactured stone siding. This stone siding that caught his eye was more broken up shards of concrete than it was a product replicating a natural stone. In a monumental moment of curiosity, he began to question, “How could we do this better?”

This simple question turned into obsession; one that evolved over the years to follow. With a passion for innovation, and an unrelenting persistence through trial and error, he began to perfect a new method to hand cast and replicate the intricacy and fine detail of natural stone as it’s found in nature.

Through collection of rocks while out on hikes, a deep library of natural stone for casting began to take shape, a practice our team can’t help but do to this day when stumbling across a unique piece to add to the collection.

With our own manufacturing and innovations perfected, QSV grew organically in the following years to becoming a full-service turnkey company, an end-to-end solution for stone veneer and precast installation on dream homes, churches, universities, hotels, apartments, retail locations and everything in-between.

Today, QSV proudly services the eastern half of the US from the New England states down through Florida, as well as the bordering states to the east up to the Mississippi River. Here in 2024 we remain family owned and operated with over 500 years of combined experience in the stone veneer industry standing behind our leadership team.

Rooted within our name, the core values our company was built on from the beginning have never changed:

Quality. Sustainability. Value. Innovation.

Associations, Affiliations

The Cornerstones of Quality Stone Veneer, Inc.

Safety

"We Choose Safety First" is not just a slogan; we live it everyday. We pride ourselves on our longstanding reputation as a safety-minded organization. Internally, all meetings begin with a monthly safety slogan. Employees are encouraged to participate in sharing thoughts on safety for an entry into a monthly Safety Incentive Drawing. Field managers are OSHA Certified, holding tool box talks with our installation team in the field regularly.

Quality Product

![]()

QSV is constantly striving to provide a quality product and intricately detailed installation. Our approach to developing products is unique to the industry, hand crafting the fine detail of stone as it's found in nature. Our own processes and innovations have been developed over the 45 years we've been in business, consistently refining and building on our previous endeavors. We seek to approach each project with commitment, diligence, and attention to detail.

Installation Expertise

![]()

We understand designing, sourcing and installing stone veneer isn’t easy, and strict project deadlines and budgets make it difficult to manage the process on your own. QSV is a turnkey company, meaning we handle both the manufacturing and installation of our own product. From estimation through project completion, QSV ensures your project is done beautifully, correctly, and on time.

Learn More about our Installation Here

Customer Service

![]()

We have defined our company's purpose as to "Serve Customers and Coworkers Equally." It is of great importance we maintain the highest level of customer service to all, both internal and external. Our local representatives work hand in hand with our customers, a personalized approach to bring their vision from Dream to Reality. We strive to build relationships with compassion and respect, from our administrative operations to the jobsite.

Quality Stone Veneer is the manufacturer, distributor, and end installer of the product when installation is desired. We sell our product direct to our customer, working hands on with them on their vision. Our customers bypass the markup costs often associated with purchasing products through second party distributors or wholesalers. Our products are made by hand in one of two of our main manufacturing facilities here in the US.

As a full service turnkey company, we supply and install our product on projects large and small, from multi-building apartment complexes, intricately detailed custom homes, mall and retail spaces, hotels, schedule-driven production homes, remodels, fireplaces, and everything in-between. We are an end-to-end solution for stone veneer manufacturing and to-code installation.

Our in-house, trained and certified project management teams, or field managers, are safety-minded experts of the trade. A field manager is assigned to manage each project with diligence and attention to detail. In a turnkey package, your project will be provided a field manager as your single line of communication through your project’s completion.

A Few of Our Partners

Quality Stone Veneer is proud to partner with homeowners, as well the finest architectural firms, home builders, hospitality and retail developers, and commercial contractors east of the Mississippi.

“The variety of stone and colors is great. It was hard to choose. My house had brick on it to start and it looked " formal". Deciding to put stone veneer (and a new porch) made a HUGE difference. It looks and feels more cozy and welcoming. I love the color and variety of the stone shapes and sizes that were used . The prices were reasonable too. If I had more houses I'd do stone veneer to each one! Glad I made that choice. Great work by all, thanks again."

“Quality Stone Veneer provides an excellent service, from beginning to end. Quality Stone has an eye for detail and will go above and beyond for a customer’s specific vision. They provide accurate and honorable price quotes we can depend on and are timely to address all concerns in a professional manner. They offer a wide selection of colors and styles, sure to suit each of our customer’s needs.”

“Quality Stone has been a trusted Garman trade partner for over 30 years. We value their partnership, professionalism, and commitment to our industry. The Quality Stone team brings expertise from manufacturing through installation and have always stood behind their products and craftsmanship."

Key Moments in Our History

![lehigh-valley-pennsylvania-74RD9C5-1]()

1976 - Quality Stone Veneer, Inc. is Founded

The name Quality Stone Veneer, Inc. is coined and the very first steps towards creating the company begin to take place. Including, the beginnings of building a collection of stone found in nature while out hiking.![refton]()

1995 - Refton, PA Manufacturing Plant

QSV's manufacturing get's a massive new facility. The second plant location opens it's doors in Refton, PA immediately across the street from our administrative headquarters.![hanover-pinehills-cobble]()

1998 - Hopkinton, MA Office

QSV expands it's footprint north adding coverage to the New England States, opening an office in Hopkinton, Massachusetts 40 minutes outside of Boston. Partnerships begin with a diverse portfolio of builders in New York, Massachusetts, Connecticut, Rhode Island, New Hampshire and beyond.![tower-city]()

2003 - Tower City, PA Manufacturing Plant

The Tower City, PA plant opens adding 10,000 square feet of additional manufacturing and warehouse space capacity.![Thompsontown-2]()

2004 - Thompsontown, PA Office

QSV purchases and remodels an 1800's barn in Thompsontown, PA adding another operations hub for the east coast.![Benson copy]()

2006 - Benson, NC Manufacturing Plant

The Benson, NC manufacturing plant opens allowing more capacity for partnerships in the Carolinas and south eastern region of the US.![ridgewood-ledgestone]()

2007 - Breakthrough Product Innovation

QSV's Ledgestone style is designed, the first panelized stone style to be created. Without stones needing to be installed individually, Ledgestone opened the doors to a more easily achieved stacked stone look, in less time.

Pictured: Ledgestone on Turtle Manor in Massachusetts.

![Powder-Ridge-Drystack-Lambris-2]()

2008 - Drystack Lambris is Developed

The initial ideas an drawings for Drystack Lambris come to fruition, a brand new product innovative in shape, texture and installation. The product begins development and testing at the Long Lane location.

![clip-system]()

2010 - The Inception of the Quality Stone Veneer Clip System™

QSV begins to see a trend in projects specifying the requirement for drain mat, an additional underlayment product designed to create an airspace between the wall and stone. This added cost to stone installations.

What can we do to create a drainage space between our product and the wall system, without adding the additional cost and installation time that comes with drain mat? How can we better separate the wall and the stone product to itself to add breathability to a structure and further protect a project's longevity?

The Quality Stone Veneer Patented Clip System™ application method is invented and undergoes its first stages of development.

![Sheetz-2]()

2010 - Sheetz® Convenience Stores Partnership

QSV begins its partnership with Sheetz® convenience stores using the brand new Drystack Lambris, on their stores. Drystack Lambris in the color Powder Ridge is installed first on one of their West Virginia locations using traditional mortar and wire lath.

More stores are added throughout the future months, as QSV begins partnering with Sheetz® on a long list of remodels and new builds throughout the northeastern US.

![clip-install]()

2010 - First Clip System Project

The first Clip System project is completed with our then newly developed Cobblestone Lambris. A groove in the back of the stone pieces did not yet exist with this first version of the product. Instead, a groove was meticulously cut into the back of each piece on site to accept the galvanized clips.

![new-england-drystack-lambris]()

2012 - First Residential Clip System Projects

Cobblestone Lambris and Drystack Lambris are installed in New York on our first single family home projects to receive Clip System installations.

![clip-1]()

2012 - Benson Office Clip System Procedural Development

In June of 2012 at our Benson, NC office, QSV holds a Clip System installation meeting where company procedures and specifications for Clip System installations versus a traditional mortar and wire installations (What we call a Direct Application), are developed.

![Clip-System-Groove-1]()

2012 - The Clip System Groove

QSV begins to develop molds that include the Clip System groove behind the stone pieces. This eliminates the necessity to cut the groove manually on site with a masonry saw.

![first-clip-install]()

2013 - Drystack Lambris Installation with Integrated Groove

A Clip System installation is completed with the all new Drystack Lambris molds that now included the groove in the pieces. Installation time is significantly cut down, no longer requiring the extra step of cutting a groove in the back of each stone piece before mechanically fastening the product to the wall.

![Historic-Brick-2]()

2013 - Historic Brick, A first Clip System Compatible Thin Brick

Historic Brick, our very first panelized thin brick product is created featuring the same groove in the back of the pieces to accept the clip. A handcrafted, full depth brick look could now be achieved on projects, without the necessity of the additional structural design a full depth building brick requires.

![4-square-gospel-church]()

2016 - Foursquare Gospel Church - Lambris Style Combinations

Historic Brick, Preset Drystack and Siota Block styles, in addition to our handcrafted precast accents are uniquely installed on Foursquare Gospel Church in PA. This project is one of the first to demonstrate the profile combination capabilities of our Lambris product line.

![Clip-Starter-Strip-At-Foundation-Detail-2]()

2016 - Clip Starter Strip

In Early 2016, the Clip Starter Strip is developed, a 20 gauge galvanized metal flashing that acts as a weep screed, drip cap, and starting Clip attachment for the first row of stone. This further revolutionizes the Clip System Installation package, saving installation time with the addition of this new proprietary product.

![Big-Sky-Apartments-Clip-Starter-Strip-1]()

2016 - Big Sky Apartments

In March of 2016, Quality Stone Veneer begins work on Big Sky Apartments in Staunton, VA using the then newly developed Clip Starter Strip. Provence Cobblestone Lambris is installed via the Clip System.

![coastal-drystack-lambris]()

2019 - Springs at Castle Rock

The first Clip System project begins in Castle Rock, CO out of QSV’s Littleton office. Coastal Drystack Lambris is installed in a Clip System installation for Continental Properties.

Today